CASE COLOR HARDENING AND PERIOD BLUING

I bumped into Val Forgett during a Boy Scout’s presentation at The Summit Bechtel Reserve in the beautiful mountains of West Virginia. After a few minutes I steered the conversation to the high-grade 1873 rifles he was marketing through Navy Arms. Candidly  these are the finest production 1873 rifles I have ever seen. The case color hardening and blue is magnificent. Val recommended Wyoming Armory located in Cody. The shop is well known for traditional bluing and some of the best bone charcoal color case hardening available.

these are the finest production 1873 rifles I have ever seen. The case color hardening and blue is magnificent. Val recommended Wyoming Armory located in Cody. The shop is well known for traditional bluing and some of the best bone charcoal color case hardening available.

Off they went to Cody for the full treatment: case colors, bluing, right down to fire bluing of the screws. In less than 30 days they were returned, the revolvers were beautiful.

The progress on these revolvers were well ahead of the timeline I had imagined. So, I called Jeff Ault of Munden Enterprises to see if he could get to them immediately.

MUNDEN MASTERPIECES

Now fully engraved, blued and case color hardened my ‘51s arrived at Munden Enterprise in Butte, MT for Six-Gun Magic by Jeff Ault. Let me back up a bit, I have known Bob and Becky Munden since I was a teenager working for Hodgdon Powder Company back in the ‘70’s. Having become close, Bob tuned all my single action revolvers. With each completed revolver Bob provided a paper test target and a nickel he had shot from the sky. His Six-gun Magic enabled my open top revolvers to withstand the rigors of Cowboy Action Shooting. Early in 2011 Bob called me and said he had determined that he could reengineer my ’51 conversions much like his indestructible Option #2 Colt “Race Guns”™ used in fast draw. I was game, so off went all six revolvers to Bob’s shop in Butte, MT. He did exactly what he said and built my open tops revolvers into Option #2 Race Guns™,

virtually indestructible . Bob never offered the Option #2 Race Gun™ build for open tops in his list of gunsmithing services. Simply too time consuming when compared to the Option #2 Race Gun’s built on Colt SAA and Ruger single actions. Sadly, Bob passed away December 10, 2012 two months after my last visit to Butte. Fortunately for all of us he had long been tutoring an understudy, Jeff Ault. Jeff studied Bob’s method of Six-gun Magic including the Option #2 Race Gun build technique for Colt style open top revolvers. Jeff, much like Bob, is a meticulous pistolsmith especially important with building indestructible single action revolvers. Colt open top revolver design is not robust enough for cowboy action shooting. We hurl thousands of rounds down range that wreck stock revolvers. The work performed is more akin to re-engineering these revolvers than simply tuning them.

SIXGUN MAGIC… A LITTLE HISTORY

Bob entered the game of Fast Draw as a teen during the 1950s. He would destroy Colt single action revolvers shooting thousands of rounds each week. Munden could not afford to replace a gun that he was essentially beating up. He determined exactly how parts in the gun wore out or broke, then figured out what he had to do to protect the revolver from the extreme stresses he visited upon it. Throughout his years of competition, Bob continued to improve the original design of the Colt single action. Developing several key innovations including Bob’s unique modifications of the cylinder notches and locking bolt, and coil main spring conversion.

THE OPTION #2 MUNDEN ENTERPRISES PREMIER OPEN TOP ACTION BUILD

The Option #2 build on my ’51 Conversions starts with a buttery smooth, light hammer draw. This is accomplished by eliminating the flat hammer spring and converting to a coil one. My triggers are crisp and break at 1 ½ lbs. Jeff has a proprietary flat trigger/bolt spring made to his specifications. This spring is superior at retaining tension for those of us who detail strip our revolvers on a routine basis. The cylinder hands and revolver frames are modified to accept Ruger style coil spring and plunger. For those not familiar with conversion revolvers, the flat spring is removed, back of the hand recontoured and a crescent shape piece of steel laser welded to the back. The forcing cones are cut and polished increasing accuracy and reduces barrel leading. The chamber mouths are slightly beveled for ease of loading and the chambers themselves polished mirror bright. Re-machining cylinder locks and lead-ins combined with highly specialized altering of the locking bolt to protect the cylinder locks is done. Jeff installs a Munden Bolt Stabilizer Block. Jeff custom fabricates hand fitting the block to each gun. Bolt Stabilizer Blocks protects the frames from the subsequent damage from accelerated use up to and including fanning the gun should you participate in fast draw events. Jeff, like Bob, absolutely guarantees the work for the life of the gun.

RECOIL CONTROL GRIPS

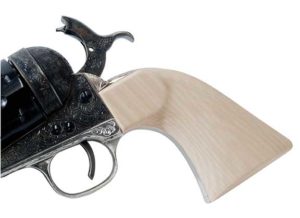

Another Bob Munden creation are the Recoil Control Grips. Bob carved out this design in the early 1960s. The grips allow for small amount of roll so I can snag the hammer but allows me to maintain my grip for fast follow up shots. Chris Whistler owner of Chisel and Plane Workshop offers these custom grips. I spoke with Chris explaining what I wanted; one-piece Ivory substitute grips made to fit my hands. Chris instructed me to make a tracing of my hand which I mailed to him. Jeff Ault forwarded my revolvers to his shop for fitting. The final product was perfectly fit to the revolvers and my hands.

Another Bob Munden creation are the Recoil Control Grips. Bob carved out this design in the early 1960s. The grips allow for small amount of roll so I can snag the hammer but allows me to maintain my grip for fast follow up shots. Chris Whistler owner of Chisel and Plane Workshop offers these custom grips. I spoke with Chris explaining what I wanted; one-piece Ivory substitute grips made to fit my hands. Chris instructed me to make a tracing of my hand which I mailed to him. Jeff Ault forwarded my revolvers to his shop for fitting. The final product was perfectly fit to the revolvers and my hands.

FINAL TOUCHES

Hickok’s 1851 Navy revolvers were described as silver mounted. That refers to them having silver plated trigger guards and backstraps. Hile Plating Silversmiths has been silver mounting my revolvers for 20 plus years. These revolvers are no exception, receiving the customary triple plating and high gloss polish.

Prior to heading out to the range I applied Dyna-Tec as I do on all my firearms designated for use with black powder. Borecoat in the bore and cylinder chambers. Gunshield on both the internal and external parts and surfaces. Dyna-Tec is a nano ceramic in a clear suspension that bonds molecularly to all metal surfaces. Borecoat when shooting black powder allows you to shoot longer without the soot buildup and simplifies cleanup. Gunshield protects the case colors and bluing from all manner of corrosion and reduces friction to point that lubrication for some is unwarranted.

Prior to heading out to the range I applied Dyna-Tec as I do on all my firearms designated for use with black powder. Borecoat in the bore and cylinder chambers. Gunshield on both the internal and external parts and surfaces. Dyna-Tec is a nano ceramic in a clear suspension that bonds molecularly to all metal surfaces. Borecoat when shooting black powder allows you to shoot longer without the soot buildup and simplifies cleanup. Gunshield protects the case colors and bluing from all manner of corrosion and reduces friction to point that lubrication for some is unwarranted.

I love your new guns! Well worth waiting for.

Really nice. Almost too nice to shoot. I did not know Fred was still working.

Wow! & Wow! Beautiful!!!!!

Does anyone know where I can find more info on the beveled ejector rod? I would love to do that to mine so I don’t have to fight to reload it.

Levi,

I believe you are referring to the taper of the ejector rod. If so, you can do that yourself with a drill press, emery cloth and cold blue. The taper allows for the easy ejection of spent casings by not impacting the chamber wall prior to inserting into the empty case.